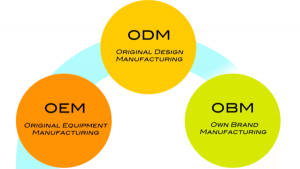

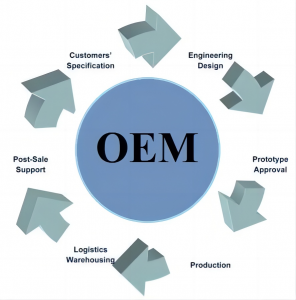

OEM is the abbreviation of Original Equipment Manufacturer in English, also known as fixed-point production, commonly known as OEM (production), the basic meaning is that brand manufacturers do not directly produce products, but use their own key core technologies to design and develop new products. To control the sales channels, the original equipment manufacturer entrusts other manufacturers of similar products to produce the specific processing tasks through contract ordering, and then buys out the ordered products at a low price, and directly affixes its own brand trademark. This cooperation method of entrusting others to produce is called OEM for short. The manufacturer undertaking the processing task is called an OEM manufacturer, and the products it produces are called OEM products.

In the auto repair industry, original equipment manufacturer (OEM) refers to the original product used by the car manufacturer. These are distinct from aftermarket parts, which are made by third-party manufacturers but may be compatible with the same vehicle. OEM parts are often preferable to aftermarket parts because they are specifically designed to fit your vehicle’s needs and are likely to be of higher quality, as well as being closer to the original. Although aftermarket parts tend to be cheaper, they can also wear out more often.

An OEM is the opposite of a third-party manufacturer who produces parts that are sold in the aftermarket. OEM refers to something made specifically for the original product, while aftermarket refers to a device made by another company that consumers can use as a replacement.

Jiangsu Dijianna is OEM-grade cat using premium Heavy Metals to meet OEM’s emissions targets. Each piece is made with stainless steel mandrel-bent piping, laser-cut flanges, and OE-style connections, and specialize in 90% OEM/ODM production. Most systems include new gaskets or clamps. This is an aftermarket piece priced significantly lower than the Genuine OEM equivalent. Although Genuine OEM will be a higher quality overall it comes with a price tag typically 3-5x higher

producer benefits

Compared with the buyer, the supplier is in a relatively passive position, however, it is still profitable to adopt the OEM method.

1. Enter the international market and participate in international competition

The competition in domestic home appliances and other industries is becoming increasingly fierce, and the market is becoming saturated. In order to expand the market, some domestic manufacturing enterprises do OEM for foreign brands. Enhanced corporate global awareness.

2. Scale production, reduce cost

Economies of scale generally exist in modern production, that is, the unit cost tends to decrease with the expansion of output scale. This may come from the deepening of specialization and the allocation of fixed costs. If the enterprise itself has such a situation of excess production capacity, the effect of cost reduction will be more obvious. Participating in OEM supply means expanding the output scale, which not only increases product sales, but also reduces costs.

3. Learn from experience and improve management

Enterprises that provide OEM often play an important role in the product supply chain of the OEM buyer. The OEM buyer can have strong strength in production management, marketing, product development, etc. During the cooperation process, the OEM supplier can improve product quality. The management of control, cost control, operating efficiency control, etc. organizes production according to the requirements of the buyer, and improves the management level of the enterprise with advanced organizational control and accumulated experience from “learning by doing”.

Producer disadvantages

Most of China’s processing, production and export enterprises developed under the background of industrial transfer from developed countries, so most of their markets are overseas. With the decline of labor cost advantages and the expansion of the industry’s production scale, these enterprises are generally facing problems such as declining profit margins and slowing down of development speed. Many enterprises are making attempts in secondary development. However, when such enterprises think about and try to develop strategies, there are three undesirable symptoms that need to be paid attention to urgently.

1. Scale expansion — the weakness behind the growth, the expanded production scale, although it can improve the competitive position of the enterprise in the industry, but it has not improved its position in the industrial chain, and it will also cause further damage to the market links. Dependence, the position may become more passive 2. Cost advantage – the weakness behind success. With the intensification of industry competition, the development of specific enterprises has begun to be constrained by the lack of unique competitive advantages. Processing and export-oriented enterprises have long relied on labor price advantages. Emphasis is placed on the cultivation of such capabilities. Therefore, for such processing and export-oriented enterprises, this factor that brings success also becomes a hidden danger for the further development of the enterprise in turn.

Post time: Feb-06-2023