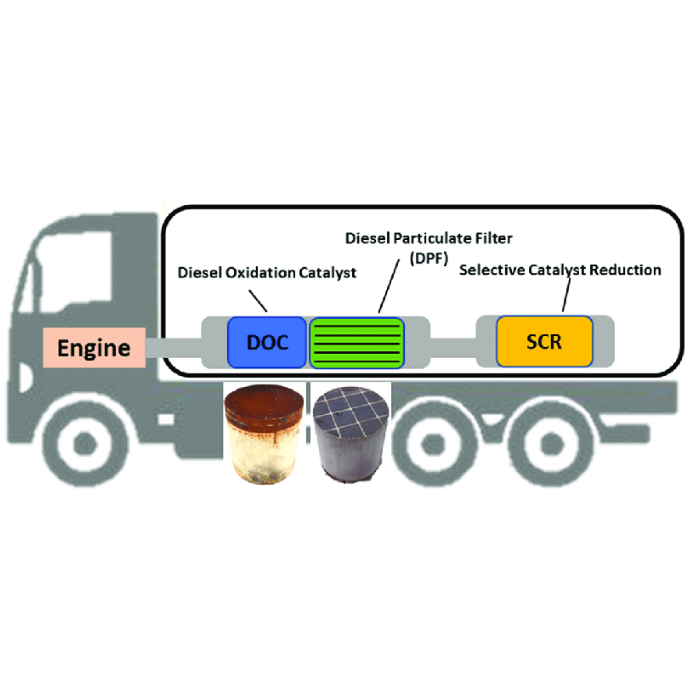

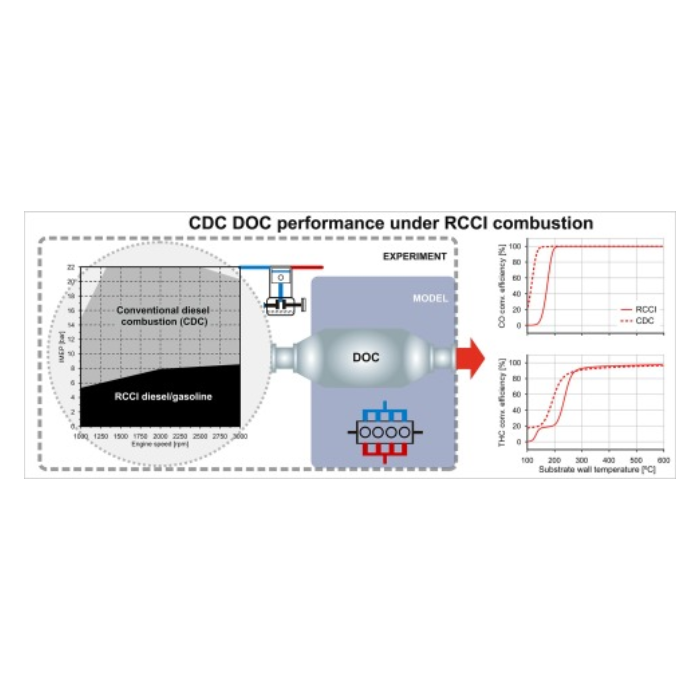

Our premium DOC catalysts have been meticulously crafted and specially formulated to effectively eliminate or diminish harmful components from emissions, all while minimizing pressure drop. Our standard units boast an impressive reduction rate of over 90% for carbon monoxide (CO) emissions, as well as high reduction levels for unburned hydrocarbons (UHC), aldehydes (a primary contributor to diesel exhaust odor), and diesel particulate matter (DPM). However, with custom configured units, even higher levels of reduction are possible, contingent upon the specific operating conditions of the engine. Our Diesel Oxidation Catalysts are suitable for use in both automotive and industrial applications.

DOCs are coated with precious metals and over time these deteriorate causing the DOC to fail. The DOC has no moving parts, resulting in it having a long lifecycle. Therefore 80% of DOC and DPF failures are premature due to engine-related issues.

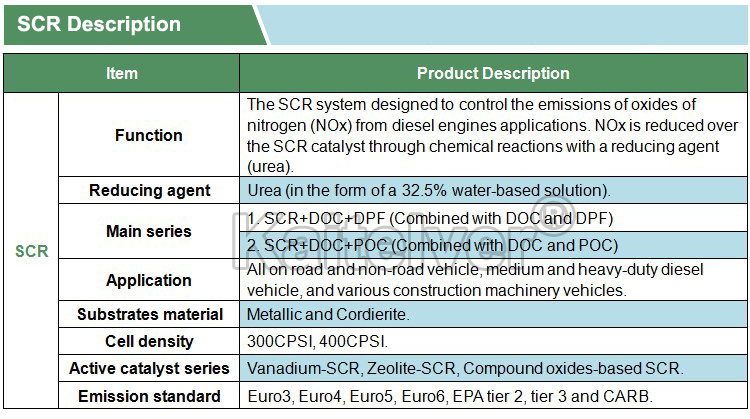

SCR catalysts are designed and employed specifically for the purpose of NOx aftertreatment in diesel engines, utilizing a two-stage process for effective reduction of harmful emissions. The first stage, known as the Oxidation Stage, targets CO and HC reduction, while the second stage, the SCR stage, targets NOx reduction. The two stages work in conjunction to significantly decrease harmful emissions, thereby ensuring compliance with the strictest regulatory standards.

In the mixing section, either ammonia or aqueous urea is introduced into the exhaust stream. Urea is often preferred over ammonia due to its lower toxicity, ease of transportation and storage, and permitting convenience. Urea undergoes hydrolysis in the system and decomposes in the exhaust stream, forming ammonia.

Each SCR catalyst is custom-formulated, designed, and manufactured to meet the unique requirements of our clients, facilitating maximum reduction of NOx emissions while offering a cost-effective solution.

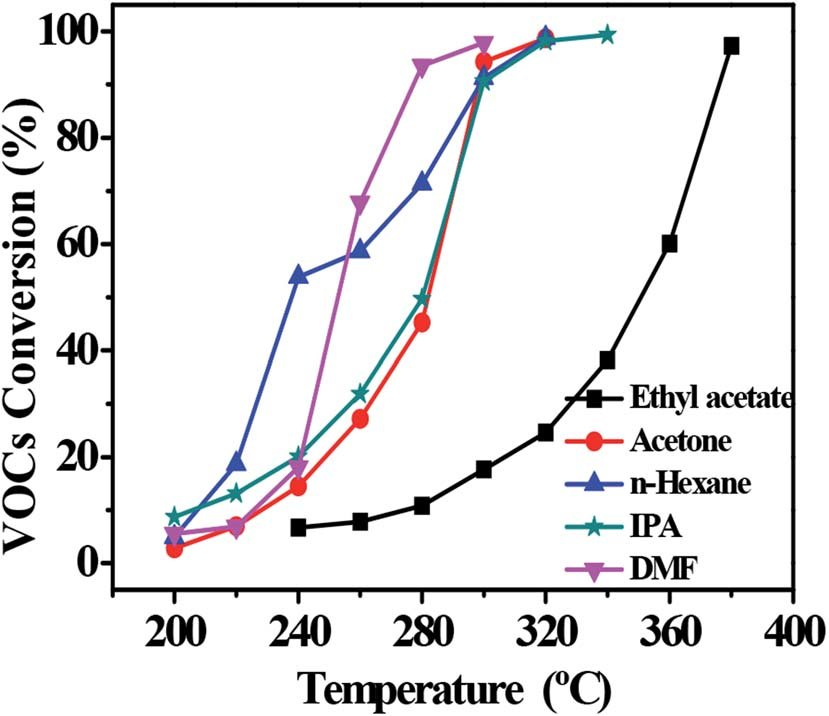

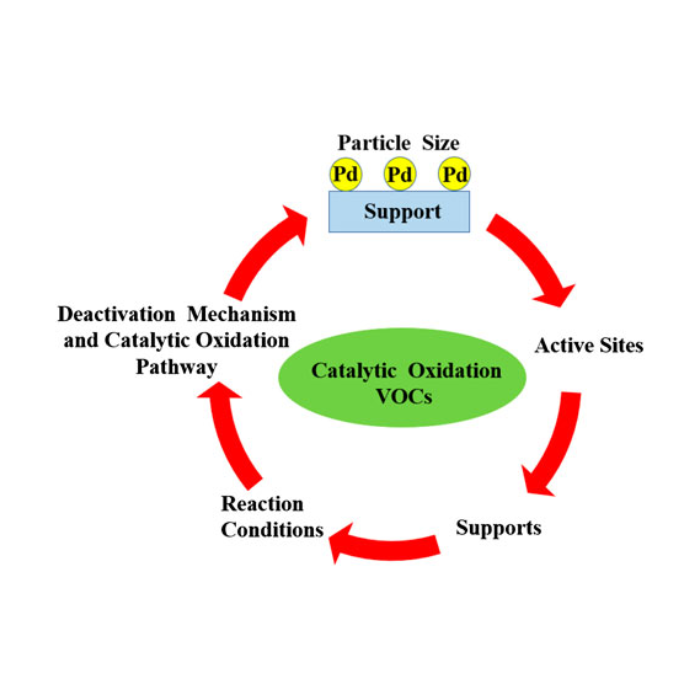

Our VOC product series has been designed with high destruction efficiencies and durability in mind, making them ideal for air pollution control applications. These products are available with both metal and ceramic substrates, and have been engineered to provide superior performance at competitive prices. By using our VOC products, customers can achieve compliance with air quality regulations without exceeding their budgetary constraints. Our products are backed by empirical data showing their efficacy in controlling VOC emissions, with destruction efficiencies exceeding 99% in many cases.