DJN Exhaust has a core team of experts who have been engaged in catalyst technology research and development, production preparation and technical services for 15 years in the industry, employs a number of doctoral supervisors and professors as technical support, and conducts industry-university-research cooperation with the School of Chemistry of Beijing University of Aeronautics and Astronautics. International advanced product development and application provide reliable technical support.

R&D CENTER

Physical and Chemical Analysis Laboratory

The laboratory is equipped with small sand mills, analytical balances, pure water machines, ovens, high-temperature muffle furnaces, ultrasonic cleaners, constant temperature water baths and other conventional instruments, which are mainly used for routine chemical analysis of raw materials, catalyst process development, formula screening, sample Preparation, and routine performance testing.

Instrumental Analysis Laboratory

The laboratory is equipped with an American Quanta specific surface area and pore size analyzer for material specific surface area, pore volume, and pore size testing, an American Quanta chemical adsorption instrument for TPR and TPO testing of materials, and a British Vernal laser particle size analyzer. For the particle size test of raw materials and flurries, Brook field micrometer is used for slurry viscosity test, PE inductively coupled plasma emission spectrometer is used for precious metal and impurity content test, and back pressure tester is used for carrier and catalyst back pressure test.

Performance evaluation laboratory

The laboratory is equipped with a catalyst sample evaluation system, a starting bench test system and a vehicle oxygen storage test system, which can evaluate the performance of the catalyst in three dimensions from the catalyst sample to the engine and then to the vehicle.

TESTING

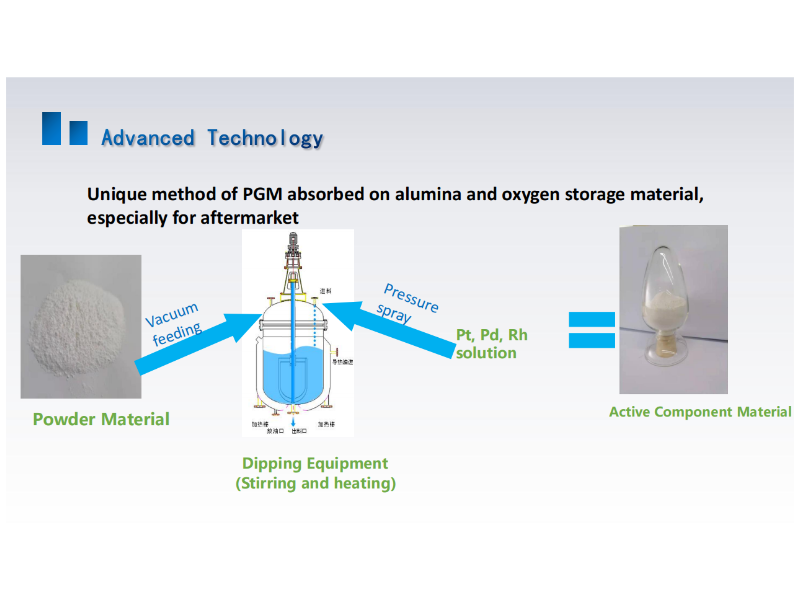

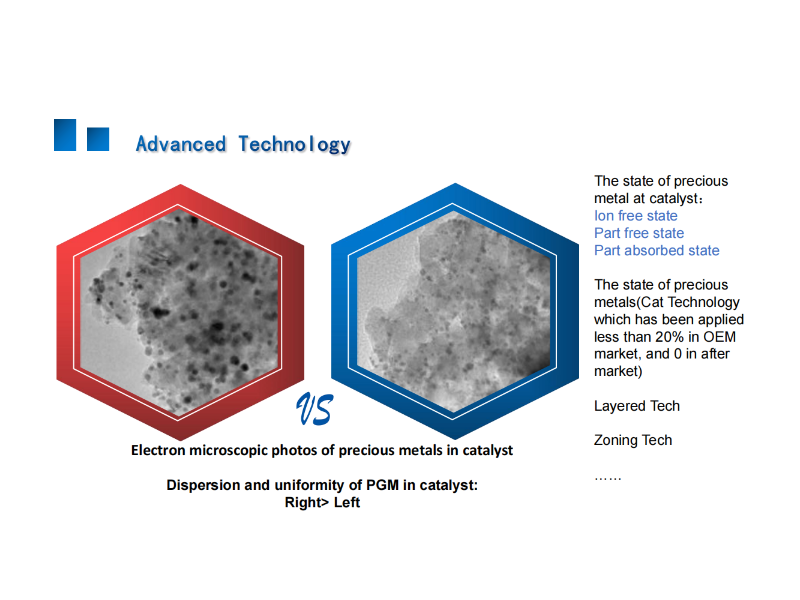

1. Adopt a new generation of high-temperature resistant coating materials (high-temperature resistant alumina and oxygen storage materials) to further improve the high-temperature aging resistance of the catalyst.

2. Using the difference in thermal conductivity between A1203 and oxygen storage materials, rational distribution of coating structure promotes faster light-off of cold-start HC.

3. Optimize the interaction between precious metals and coating materials, effectively ensure the high conversion rate of HC/OX after aging, optimize the location of additives on coating materials, and improve the high temperature resistance of coatings and precious metals.

| Meet higher emission requirements | ||

| Applied Technology | Cutting-edge technology | |

| Measure mentsto solve the problem of rapid ignition | High dispersion tech of PGM has been applied to the structure. Precious metal precursor area loading technology. Structure design (Tight coupling, vehicle matching. Substrate technology. |

Low temperature active material technology. HC collecting Material Technology. |

| Measures to improve the reducing capacity of poor combustion NOx | Combining techniques for different precious metal species; Storage NOx material technology. | Precious metal solution technology |

| Measures to improve oxygen storage capacity | Multi-rare earth structural material technology. | Precious metal solution technology |

| Measures to improve durability | Precious metal physical isolation anti sintering technology. High temperature pretreatment technology for coating materials; Failure analysis techniques. |

Structural optimization design Precious metal solution technology |

| Cost optimization measures | Precious metal precursor high dispersion technology Load process technology |

Oxygen storage material technology |

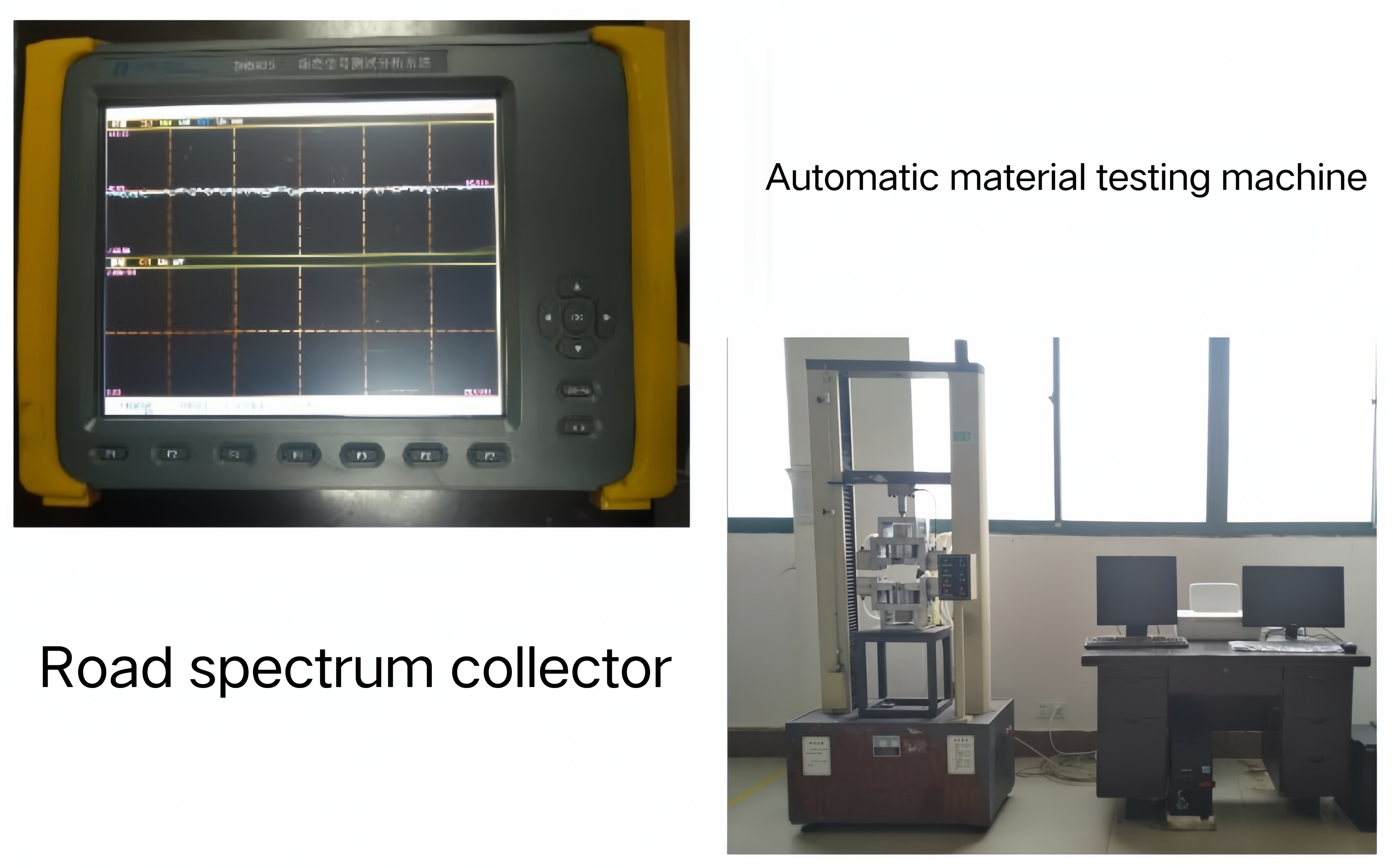

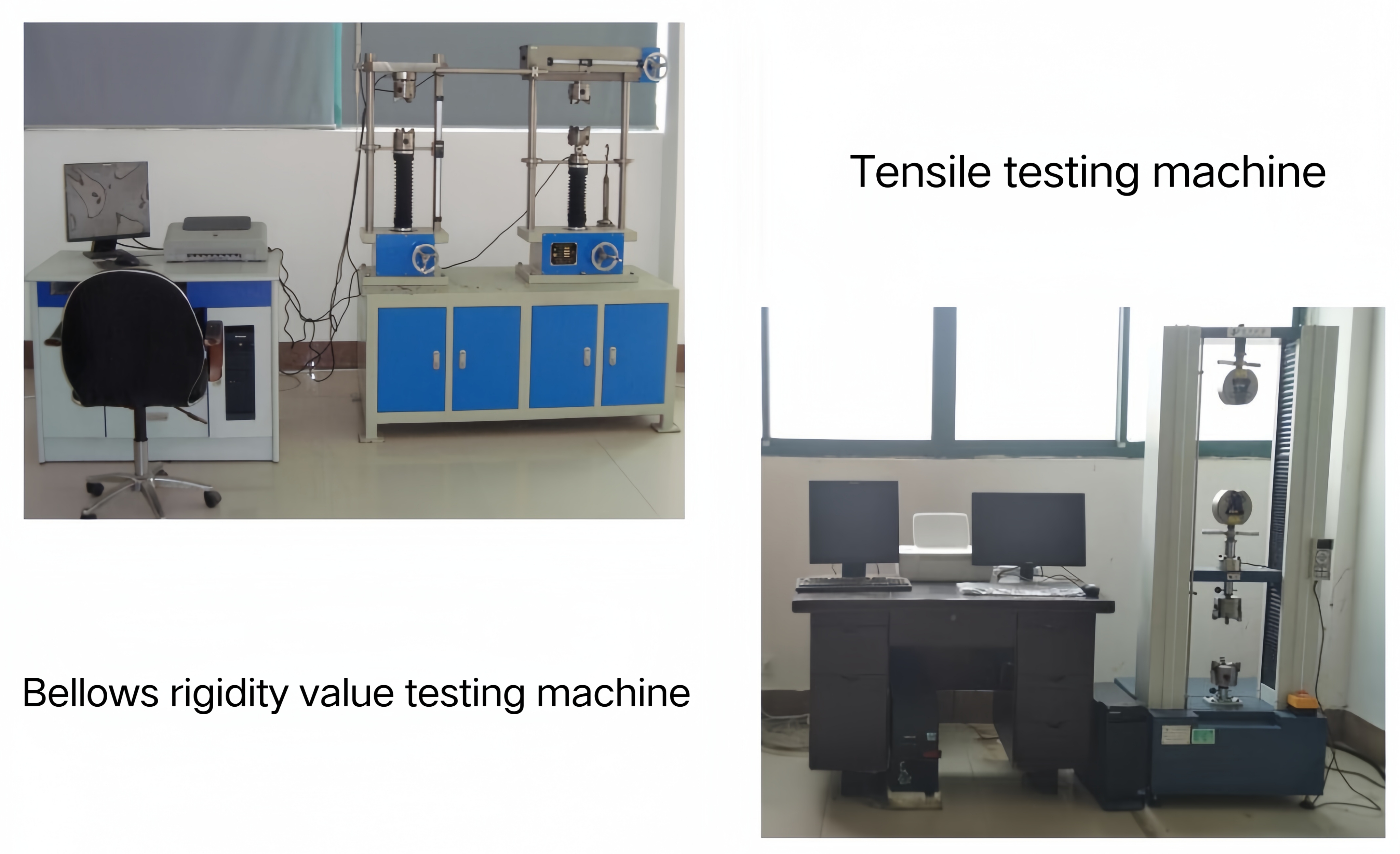

CNC Universal Testing Machine

Usage: it can do physical testing for the material and product, including comprehensibility, bending rigidity, cutting rigidity, and stretching rigidity.

Metal graphic Microscope

Usage: It can analyze the welding sensitivity of component.

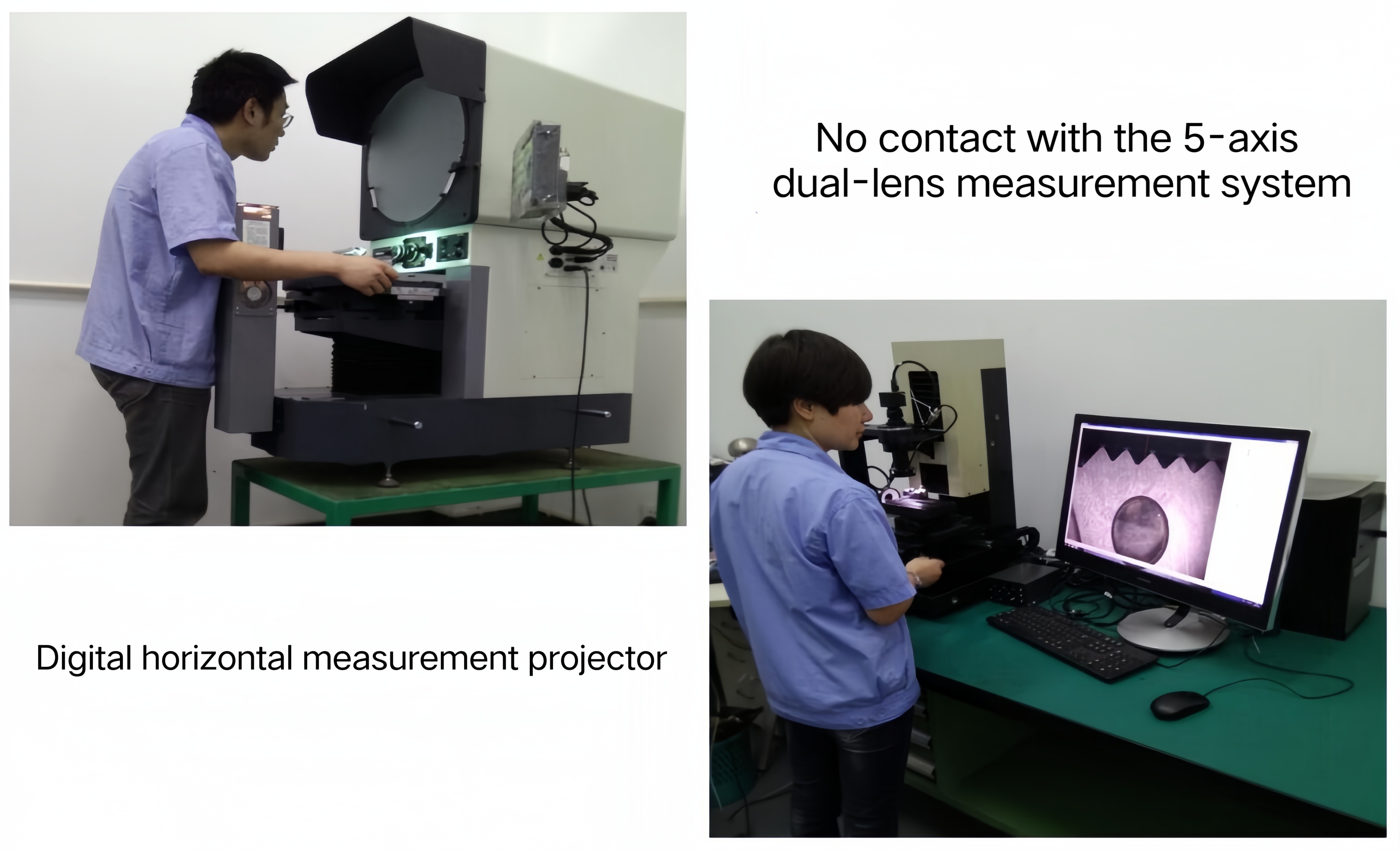

Three-Coordinates Measuring Machine Usage: It can inspect the space dimension of the component.

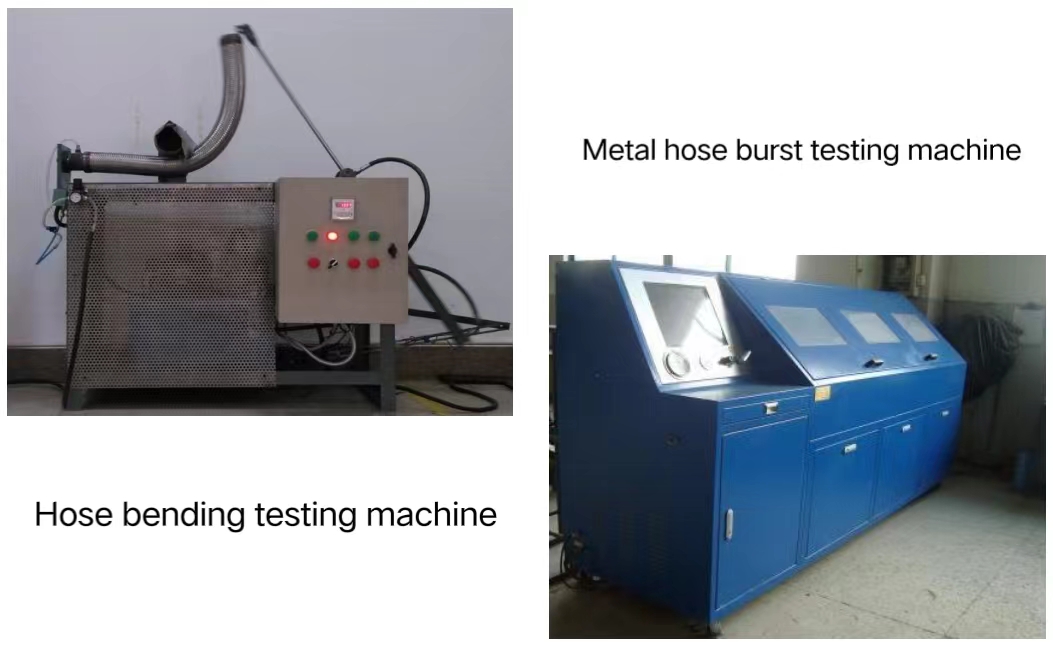

Endurance testing machine and the high-frequency heating machine usage: It can do endurance tests and high-temperature resistant tests for the product. Including stretch endurance, cutting high-temperature endurance, bending high-temperature endurance, and high-temperature resistant.

3D Image Measuring Instrument

Usage: lt can measure and analyze the cutting dimension of the component.

Generally, the product testing will be tested in our workshop and sometimes we will do the testing in the outside laboratory.

We will take 5%-10% of each order to process the testing, including compress rigidity, bending rigidity, cutting rigidity, stretching rigidity.

Stretch endurance, cutting high-temperature endurance, bending high-temperature endurance, and high-temperature resistance.

For 3D testing, we have developed substantial product development capabilities on the basis of modern business administration and quality control systems, advanced production equipment, and strict testing practice, we can make flexible pipes with a nominal diameter ranging from 1" to 4", available in more than 100 specifications, with an annual output of above 8 million flexible pipes for the automobile exhaust system. Now we are the OEM supplier for GUANGZHOU HONDA and GUANGZHOU TOYOTA.

To guarantee our product quality, we have a well-established testing center, the types of equipment include a 5,000N Numerical controlled tester that is capable of testing flexible pipes' rigidity and material physical properties; a durability tester that can be used to test the duration of the flexible pipe in different situations.

Manufacturing

Catalytic converter

1CATALYST COATING

2 HIGH-TEMPERATURE ROSTING

3 LABORATORY TESTING

4 BENDING

5 ENCAPSULATION

6 ROBOT WELDING

7 LASER MARKING

8 PROTECTIVE PACKING

9 PALLET PACKING

Flexible pipe