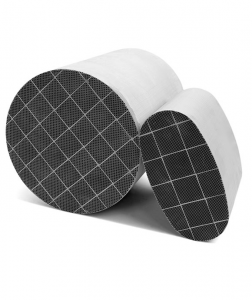

A diesel particulate filter (DPF) is a device used to reduce the content of tiny particulate matter in diesel engine exhaust. It is composed of many fine-pore filter elements that can capture particulate matter and convert it into harmless substances through a series of chemical reactions. This article will introduce the working principle, advantages and maintenance methods of DPF.

First, the working principle of DPF is to purify exhaust gas by capturing particulate matter in diesel engine exhaust. When exhaust gas passes through the DPF, particulate matter is captured by the filter element and accumulated inside it. As particulate matter accumulates, the pressure on the DPF will rise. When the pressure reaches a certain level, the DPF will automatically regenerate to remove particulate matter on the filter element. The regeneration process is divided into two methods: active regeneration and passive regeneration.

Active regeneration increases the exhaust gas temperature by increasing the fuel injection volume of the diesel engine, thereby promoting the oxidation of particulate matter. This process requires the engine to operate at high speed or under high load conditions to generate a sufficiently high exhaust temperature. At the same time, regeneration also requires appropriate oxygen supply, which is generally achieved by increasing the intake air volume and reducing the exhaust gas circulation (EGR).

Passive regeneration uses a catalyst to oxidize particulate matter at a lower temperature. In this case, the DPF catalyzes the nitrogen oxides (NOx) in the exhaust gas and generates enough heat to oxidize the particulate matter. Therefore, this process is particularly important for diesel engines operating at low speeds or under light load conditions.

In addition to its working principle, DPF has many advantages. First, it can effectively capture and reduce the concentration of particulate matter emitted by diesel engines, reducing environmental pollution. Secondly, DPF does not require manual maintenance and can automatically perform the regeneration process, extending the service life of the filter element and reducing maintenance costs. In addition, DPF can reduce fuel consumption and improve engine combustion efficiency.

However, DPF maintenance is also very important. First of all, driving habits have an important impact on the cleaning effect of DPF. Long-term low-speed driving or frequent short-distance driving will cause the DPF to be unable to regenerate at lower temperatures, causing the filter element to become clogged. Therefore, regular high-speed driving can help clean the DPF. Secondly, using low-quality diesel fuel will increase the generation rate of particulate matter and accelerate the clogging of the DPF. Choose high-quality diesel fuel to reduce the production of particulate matter.

In short, the diesel particulate filter is an effective device for reducing exhaust particulate matter emissions from diesel engines. It protects the environment and human health by capturing and reducing particulate matter concentrations, and improves engine efficiency. Correct use and maintenance of DPF can extend its service life and reduce maintenance costs. Therefore, for vehicles using diesel engines, it is very important to install and maintain a DPF.

Post time: Nov-26-2023