With the continuous improvement of the national automobile exhaust emission standards, the catalyst, as one of the key components of the exhaust gas purification, is also constantly being improved and optimized. National six GBD catalyst is a high-performance tail gas treatment catalyst, with higher conversion efficiency and longer service life. This paper will introduce the process of national VI GBD packaging process, and analyze the preparation process and process points in detail.

The packaging design matching of automobile catalytic converter is mainly the design matching of carrier (with coating), liner and shell. Carrier is an important part of the catalyst, plays a decisive role in the performance of catalyst, according to the normal range of GBD, by the liner and carrier data, determine the shell diameter, shell diameter according to certain size, can realize GBD within the design scope, realize the design of catalytic converter package design matching;

The three-way catalytic converter GBD packaging equipment consists of carrier diameter measuring equipment, carrier press loading equipment, shell shrinkage diameter measuring equipment, automatic identification system and control system, and the whole line operator has 2-3 people.

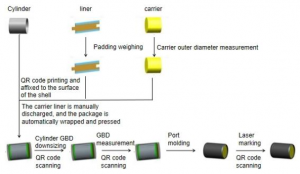

Horizontal carrier servo pressure installation

weight parameters to the server to calculate the GBD parameters. The carrier press-loading equipment pushes the carrier into the shell, records the thrust peak of the push mechanism, and sends the thrust peak to the server as the information associated with the two-dimensional code. The diameter shrinkage equipment calculates the diameter shrinkage parameters of each product in real time according to the previously measured carrier diameter and pad weight, and controls the diameter shrinkage operation in real time. At the same time sends the diameter shrinkage parameters to the server as the information associated with the two-dimensional code.After the completion of the diameter reduction,the automatic identification system will automatically generate and print the QR code according to the requirements, and paste it to the corresponding product. Before the packaging of the carrier and the liner, scan the QR code of the carrier and the liner, then measure the diameter of the carrier, the weight and dimensions of the liner, after the computer obtains the information, calculate the diameter of the shell contraction through the internal setting program, control the data exchange with the PLC, and finally realize the control of the outer diameter of the ternary catalytic converter shell.

The packaging force will have a great impact on the catalytic converter system: (1) the impact on the shell: too large load will lead to the physical deformation or damage of the cylinder, the shell or solder point rupture, noise gas leakage, the disappearance of the carrier holding force, catalyst failure and other consequences.(2) Impact on the liner: excessive compression, torsion, and vibration load will damage the pad and lead to the weakening of the clamping force (3) the impact on the carrier: too large or irregular clamping force will lead to the carrier rupture and crushing, reduce the catalytic effect, exhaust system blockage / exhaust back pressure increase

Therefore, the strict control of the packaging pressure can ensure the packaging quality and maximize the catalytic effect. CAT will conduct strict testing and evaluation of the prepared national VI GBD catalyst to ensure that its performance and quality meet the standard requirements. Common tests include specific surface area, pore size distribution, and catalytic performance. Through these test results, determine whether the catalyst meets the specified performance requirements. The catalysts that pass the test can be packaged and stored, and prepared for subsequent assembly of vehicle exhaust treatment units.

This paper introduces the packaging process of CAT catalyst, which are crucial for the preparation of catalysts with high performance and high stability. Through the continuous optimization and improvement of the packaging process, the national six GBD catalyst will play a better effect in the automobile exhaust treatment. With the further development of technology, on the basis of meeting vehicle emission standards and market demand, CAT will continuously optimize the packaging technology to ensure that CAT product process plays an important role in improving the efficiency of vehicle exhaust purification and protecting the environment.

Post time: Nov-07-2023