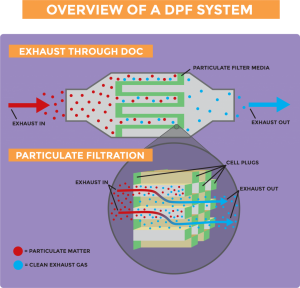

DPF=Diesel Particulate Filter,A device installed in the exhaust system of a diesel vehicle that captures diesel combustion fumes and filters carbon particles to reduce particulate matter (PM) in the exhaust. When there are too many carbon particles captured to a certain extent, the ECU driving computer will carry out “filter regeneration”, burning the carbon particles in the filter into carbon dioxide to discharge, so as to purify the filter and maintain the filtration function, referred to as DPF.

PM refers to solid or liquid particulate matter in the atmosphere. The exhaust PM of vehicle diesel engine refers to all the substances collected from the filter medium stipulated by the state when the temperature is lower than 53℃ after the engine exhaust is diluted by the purified air. The PM emitted by diesel vehicles is composed of a variety of particles with different particle sizes, whose particle size range can reach 3 orders of magnitude or higher. They will reach different tissue positions of human body and have different effects on human health.

DPF can effectively purify 70% — 90% of the particles in the exhaust, which is one of the most effective and direct methods to purify diesel particulate matter.

In simple terms, the diesel carbon particulate filter combined with a ternary catalyst converter is a self-heating filter that reduces black smoke emissions from diesel combustion. Because of the physical nature of diesel engines, the exhaust contains black soot particles, so the stereotype of diesel cars in the past is “squid cars”. With rising environmental awareness and advanced technology, today’s diesel vehicles equipped with such devices can significantly reduce black smoke, in order to meet the requirements of environmental regulations. All the carbon particles produced by diesel combustion are intercepted by the device and stored temporarily. Hot gas from the engine is used to burn the carbon particles stored in the filter, decompose them, oxidise them into carbon dioxide, and then emit them through the exhaust system.

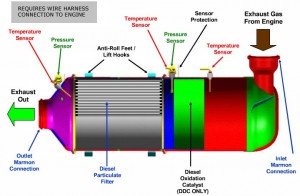

DPF is installed on the exhaust pipe of diesel engine. PM is adsorbed and filtered by filter element when exhaust passes through. However, with the increase of working time, the PM inside the filter element increases, leading to the increase of exhaust back pressure, which will affect the power performance and economy of diesel engine. According to different trigger conditions, the DPF removes the deposited carbon particles in time through catalytic oxidation, so that the filter can return to its initial working state, which is what we call “regeneration”. Regeneration is a periodic working process after a certain period of normal operation of the vehicle, which is a significant feature of DPF technology.

Generally speaking, DPF regeneration can be divided into passive regeneration and active regeneration. Passive regeneration refers to the use of oxidation components in exhaust products to consume the particulate matter in DPF. It is automatically completed when the vehicle is running, without the need for manual intervention of computers and humans, so the realization of passive regeneration function saves oil and labor. Active regeneration, on the other hand, requires the use of additional energy generated by the engine. It requires the engine to raise the temperature of the exhaust gas treatment system to between 250 degrees and 400 degrees. Only at this temperature can the particles in the DPF be consumed, that is, decomposed into harmless substances.

we return back to work from our Spring Festivalholiday with full energetic and full confidenceですwe believein that 2023 will be better. lf anything we can do for you,or if you have any issue planning order enquirylist,please feel free to contact us, we are ready to service ofyou at any moment,hope that in our joint efforts the 2023will be more prosperity than everです。

Post time: Jan-30-2023