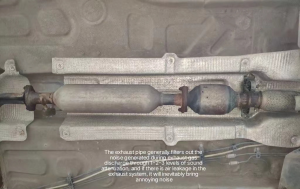

The engine sound attenuation system is responsible for reducing the noise of engine exhaust emissions, and through 1-2-3 levels of sound attenuation, the noise generated during exhaust gas emissions is filtered and discharged at one time. If we notice that the engine is suddenly loud while driving, accompanied by a “pop” leaking sound, it may be that your exhaust pipe is leaking.

The front and rear and size of the air leakage also determine the size of the abnormal noise. The different sounds also change up and down with the engine speed. If you face the situation of exhaust pipe cracking, I believe many people will choose to replace the exhaust pipe, but what I share today is not to replace the exhaust pipe to perfectly solve the exhaust pipe cracking and leakage solution.

If there is no engine exhaust system, the exhaust gas of the engine is directly discharged, and the noise is quite large. After installing a silencer, exhaust noise can be minimized. If there is a partial air leak in the sound attenuation system, the noise will also increase. The closer to the side of the engine leak, the louder the noise will be. Today’s case focuses on the mid-rear section of the exhaust.

Compared to air leakage at the pipe interface, there are more cases of air leakage caused by cracking of the corrugated hose. The walls of the tube here are very weak, and a slight scraping can lead to internal fractures and perforations, resulting in air leaks. However, most manufacturers do not provide this corrugated hose, and if you replace it, you can only replace the muffler assembly. But this corrugated hose can actually be bought in the accessories market, in case of this problem, we buy a corrugated hose welded on, which can save a large part of the cost.

This is where the exhaust pipe crack was encountered this time. It is in the middle and rear break position of the exhaust pipe. The cracking is concentrated in the bending position, and it is analyzed that the inner side of the pipe wall is seriously corroded, resulting in weak local bearing force, coupled with some torsional force at the turn, so the pipeline cracking occurs.

At a bend to the back, we saw another crack in the wall of the tube. These two cracks cause early leakage of exhaust gases that do not reach the tail section of the muffler, generating noise. So how to seal these two cracks well is the key. Since the exhaust pipe is in a high temperature .

Most models located in the rear muffler will be designed with drainage holes to drain the accumulated moisture inside and avoid rust. This is normal for this kind of problem. No handling required.

In addition to the leakage of the drainage hole, sometimes we will find that there is also a leakage at the interface, mainly because the exhaust pipe interface seal does not have strong waterproofness, as long as it ensures that this part does not leak, we can completely ignore him

To solve the cracking and leakage of the pipeline, we chose the welding method, but the choice of welding equipment is still very important. Due to the small thickness of the pipe wall, breakdown is likely to occur using electric welding. The practical air welding method, the local heat is high, the open flame range is large, and the operation with the no-disassembly welding is very dangerous. So final CO2 shielded welding is the best choice.

Due to the function of partial electric welding, we must disassemble the negative pole of the battery when connecting the iron wire. No matter what part you weld, this operation is a must. If it is not disassembled, the larger current of the welding machine is likely to break through the battery or computer.

The welding process is relatively simple, and the average sheet metal technician can operate it. Welding the cracks is sufficient

If from a safety point of view, the contact distance between the exhaust pipe and the fuel tank is close, so it must be unsafe to weld on the car. However, the use of carbon oxide shielded welding, the heat is small and the spark is less, so we guarantee that there is no fuel leakage, it is completely possible to weld.

The effect after welding is still relatively good. The cracked closure has been completely blocked.

For the gurgling noise of the front chassis when we often drive, most of them are because the contact distance between the oil pan guard plate and the exhaust pipe is too close, resulting in the contact with the exhaust pipe when the shield trembles, resulting in abnormal noise.

And don’t be surprised if you notice a leak in the compression seam of your exhaust pipe, it’s not a malfunction. We just need to check regularly to avoid serious rust and perforation.

Due to the large working temperature of the exhaust pipe, its fixing bolts will also have more serious rust phenomenon. So once we are involved in the removal of the exhaust pipe, it is necessary to lubricate the fixing bolts.

Djn exhaust flexible pipe make the special Leak-Proof Design: DJN flexible pipe should have a leak-proof construction to prevent any exhaust gas leaks. This ensures that harmful gases are properly routed through the exhaust system and released outside the vehicle, reducing environmental pollution and protecting passengers from inhaling toxic fumes.

Post time: Jul-28-2023