Porous ceramics is a new type of ceramic material, because of its good permeability, low density, high hardness, large specific surface area, small thermal conductivity, high temperature resistance, corrosion resistance and other excellent properties, it is widely used in metallurgy, chemical industry , environmental protection, energy, biology, food, medicine and other fields, used as component materials such as filtration, separation, diffusion, gas distribution, heat insulation, sound absorption, chemical fillers, bioceramics, chemical sensors, catalysts and catalyst carriers.

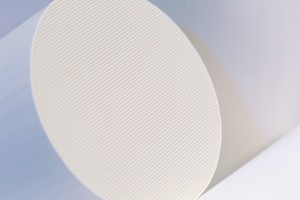

Commonly referred to as cordierite (Cordierite, 2MgO 2Al2O3 5SiO2), which belongs to the hexagonal crystal system, is a magnesium aluminum silicate mineral, which can be colorless, but usually has different shades of light blue or light purple, with glass Gloss, high transparency, but also pleochroism, can produce different colors in different directions, beautiful crystal color cordierite has a high appreciation value, and can even be used as a gem. The density of cordierite is 2.53-2.78g/cm3, and the Mohs hardness can reach 7.0-7.5. Cordierite has a low coefficient of thermal expansion and is an excellent high-temperature thermal-shock-resistant material. It is widely used as ceramic kiln sheds, saggers, electronic packaging materials, catalyst carriers, foam ceramics, bioceramics, and high-temperature heat radiation materials. The natural cordierite ore reserves are very small and the grade is low, and the commonly used cordierite bluestone materials are artificially synthesized.Due to its low thermal expansion coefficient, strong compression resistance, and strong fire resistance, it is very suitable as a three-way catalytic converter carrier,The cordierite honeycomb ceramic carrier produced by our company has the following characteristics:

1. The hole wall is thin and the specific surface area is high (the wall thickness of the product is 5mil-7.5mil);

2. Stable water absorption (water absorption: 22±2)%;

3. Good matching with various catalyst active components

4. Low coefficient of thermal expansion; (≤1.0X10-6/℃)

5. Good thermal impact performance and shock resistance (SCR carrier: resist 550°C thermal impact for 3 times, DOC: resist 600°C thermal impact for 3 times)

6. Size specification, easy to package: [φ from 4.45 inches to 10.5 inches (114mm-330mm)].

7. Good cold start performance, low ignition temperature, fast temperature rise, small air resistance and high conversion efficiency

The most important feature of cordierite porous ceramics is its porosity, and the key and difficulty in its preparation is the formation of its porous structure. According to the specific use places and performance requirements of porous ceramic materials, the existing preparation processes of cordierite porous ceramics include particle accumulation method, foaming method, extrusion molding method, adding pore-forming agent method, organic foam impregnation method, sol – Gel method, gel casting method, etc.

It is characterized in that the raw material used in molding is a fully synthetic cordierite raw material, the molding process is an extrusion process, and the drying adopts a combination of tunnel type drying and box type drying furnace. The preparation method comprises the following steps: wet-grind clay, talc, alumina, and light-burned magnesium powder in a ball mill to powder particles smaller than 320 mesh; the ball-milled powder becomes mud block after pressure filtration and vacuum refining; The cordierite material is synthesized in a downdraft kiln; then the synthesized cordierite is finely ground to the required particle size; then the finely ground cordierite powder is added to a binder with MC or PVA as the main component, Honeycomb ceramics can be produced through extrusion molding process. It is mainly used in catalytic purification of automobile exhaust, dust removal and heat storage in industrial kilns, catalytic cracking of petroleum and other industries.

Cordierite can be used as a catalyst carrier. Generally, cordierite ceramics are processed into a honeycomb structure, which is conducive to filling the granular catalyst with a diameter of several millimeters in the honeycomb carrier, which can improve the use efficiency of the catalyst. The main mechanism of action is in the catalytic reaction. The medium makes the catalyst have a proper shape and good mechanical strength, so that a small amount of catalyst can be evenly dispersed. At present, the honeycomb cordierite porous ceramic carrier is most used in automobiles, which has the advantages of thin wall, high porosity, high mechanical strength, good thermal stability, and impact resistance.

Post time: Mar-14-2023