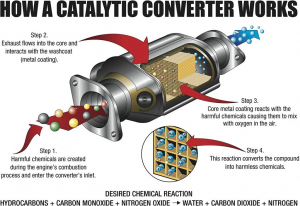

The exhaust gas from locomotive is one of the main sources of air pollution. The main pollutant of medium and heavy diesel vehicles is nitrogen oxide, whose emission is extremely serious to the ecological environment and human health. Nitrogen oxides in combustion exhaust gases are usually produced by the reaction of nitrogen compounds in the fuel and nitrogen in the air with oxygen at high temperatures. In the case of internal combustion engines, especially diesel engines and other oxygen-rich combustion engines, exhaust gases contain pollutants such as carbon monoxide (co), hydrocarbons (hc), carbon particles and nitrogen oxides. In the case of gasoline engines, oxygen in the air is burned in a chemical ratio with the fuel, and there are no carbon particles in the pollutants, which can be purified by so-called three-way catalysts.

The materials of a catalytic converter are as follows: 1. A three-way catalytic reactor is almost similar to a muffler. The exterior is double-layer stainless steel plate, and the sandwich of double-layer plate is installed with insulation material 3354 asbestos fiber felt; 2. The purifying agent is installed in the middle of the mesh separator, and the purifying agent is composed of a carrier and a catalyst. Typically, the carrier is made of alumina, and its shape is spherical, polygonal, and reticulated partition. The purifier actually acts as a catalyst, also called a catalyst; 3. The catalysts are platinum, palladium. Spraying one of these onto the carrier constitutes a purifier.

The center of the three-way catalytic converter is the multi-empty honeycomb ceramic carrier, with many holes and thin walls, so that there are many contact opportunities for the waste gas through, and it does not produce a large back pressure. The carrier material is generally made of aluminum oxide, its shape is spherical, polyprism shape and mesh partition, with appropriate water absorption, so as to coat the catalyst, and has a very low coefficient of thermal expansion, so that in the case of repeated thermal shock, do not produce large stress changes and fatigue damage. Purifier actually acts as a catalyst, also known as a catalyst. The catalyst is platinum, rhodium, palladium, one of which is sprayed on the carrier, which constitutes a purifying agent.

DJN from the carrier packaging, automatic spinning welding, to the semi-finished product manual welding, the final product production is completed by A set of standard smooth process, the introduction of advanced production lines, sophisticated equipment and complete numerical control system, including the FOO A-Panasonic Arc Welding Robot Center, Taiwan CNC pipe bending machine, etc. DJN is a high-tech enterprise engaged in catalytic converter research and automotive parts development and manufacturing, widely used in automotive emission control, DJN provides a reliable solution for automotive emission control catalysts that meet EU requirements 4/5/6, with the following advantages:

1. Excellent cold start performance and three-way window performance;

2. It has excellent high speed performance, under the environment of the high speed of 80000 h – 1, the conversion rate of catalyst can reach more than 90%;

3. Strong water thermal stability and resistance to toxic (sulfur, arsenic and phosphorus), the performance of the catalytic degradation of small;

4 High temperature resistance

5. Major emission control equipment with stable performance, reliable quality and long service life

6. High flow design

Post time: Feb-16-2023