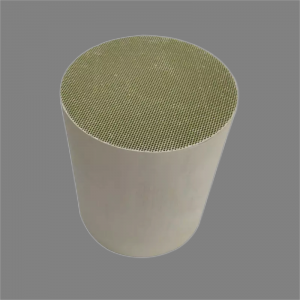

Ceramic Substrate To provide customized services Honeycomb Ceramic Substrate

Compared with traditional combustion technology, our green,energy-saving

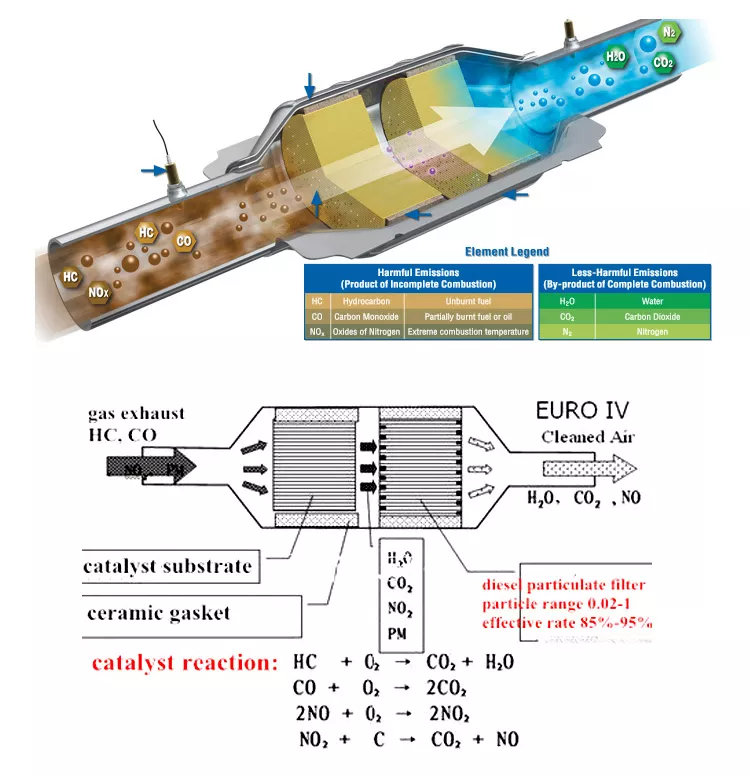

high-temperature air combustion (HTAC)system can reduce fuel intake between 20%- 50%. Productivity is also improved as oxidation burning loss is reduced by 20% and NOx emission is decreased by over 40%. The honeycomb ceramic generator has the following advantages: high heat exchange per unit volume, quick heat transfer, small airflow resistance, small heat penetration depth, and high thermal efficiency. Our elector-cast chrome corundum is synthesized at over 2000 C, producing high-quality honeycomb ceramic re generators, baffle bricks, and heat storage balls. This allows the advantages of high fractiousness under load, slag and shock resistance, and quick heat transfer. These products also have the ability for good anti-scouring, heavy volume weight, and extensive heat capacity.

| Product name | Ceramitic Honeycomb Substrate |

| Model Number | DJN0506 |

| Brand Name | DJN |

| Emission Standard: | EURO 2/3/4/5 |

| Market Type | OEM or Aftermarket |

| Overall dimension (mm) | 120*80*50mm 76*60 90*50 97*150 103*100 107*140 118.4*100 267*101.6 (300PPI) |

| Material | cordierite |

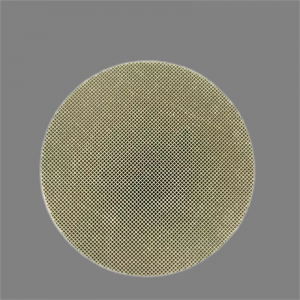

| The hole density: | 100-800 CPSI. |

| Applications | Vehicle, RTO, RCO, VOC and SCR |

| Wall Thickness: | 0.430.60.670.731.11.01.41.41.5 mm |

| Warranty | 30000 miles performance/2 years |

| Color | White/Brown |

| Shape | Round, Oval, Racetrack, or Customized |

| Certification | ISO 9001 |

| MOQ: | 50 pcs |

| Supply Ability | 1000 Piece/Pieces per Week |

| Place of Origin: | Jiangsu |

| SAMPLE ORDER: | Accept |

| Condition | new |

| Function | reduce harmful emission (CO,HC,NO) from motor vehicle Over 95% conversion efficiency; |

| Supply Ability | 1000 Piece/Pieces per Month |

| Packaging & delivery | Air bubble film and Carton Packing, inside fix the product decently with expanded material |

| Port | Shanghai/Ningbo |

| Lead time: | 10-30 days . |

| Active catalyst ingredients | Pt, Pd, Rh, and rare earth elements |

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

-

Top